mSAP

mSAP

Discover the mSAP process in PCB technology!

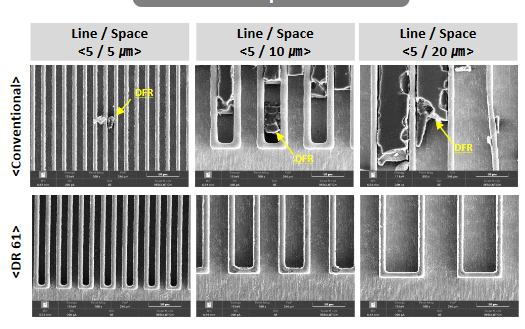

mSAP (Modified Semi Additive Process) is a pioneering technique in PCB technology that represents an alternative method of producing conductive tracks for signal transmission. In contrast to the conventional approach, the conductive tracks are not etched out of a copper layer, but are built up by adding copper to predefined areas on the PCB.

This innovative method enables more precise and efficient production of fine conductor tracks, especially in complex electronic applications where high precision and performance are required. The process helps to reduce production costs without compromising quality.

mSAP is increasingly being used in the production of high-quality printed circuit boards for sophisticated electronic devices. Industries such as telecommunications, medical technology and aerospace are benefiting from this advanced manufacturing technology.

The introduction of the mSAP process in PCB technology marks an important step towards meeting the requirements and challenges of the modern electronics industry. This innovation optimises the production of high-precision and complex printed circuit boards and enables the manufacture of electronic devices with maximum reliability and performance.

Do you already have experience or insight into the application of the mSAP process in PCB technology? We invite you to share your knowledge and have a discussion about how this technology is driving the electronics industry forward.