Welcome to the RPtec GmbH blog. Here you will find the latest news about the PCB industry.

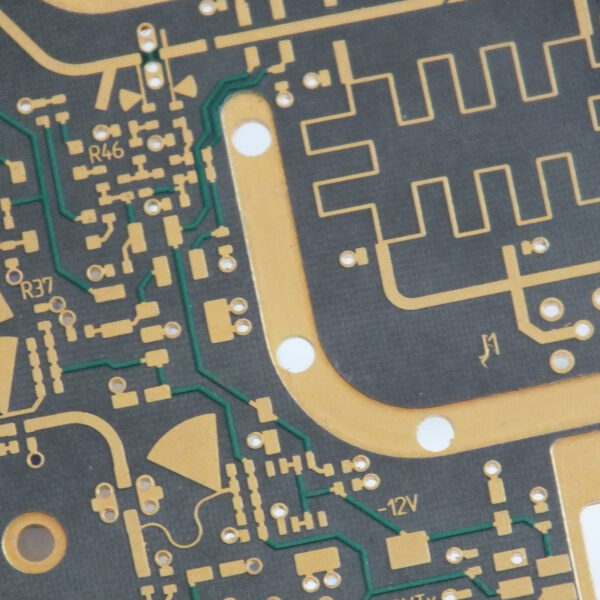

High-pass filter

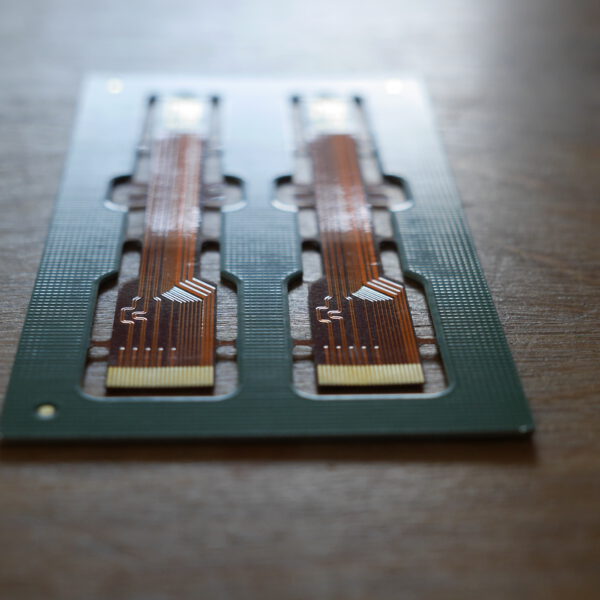

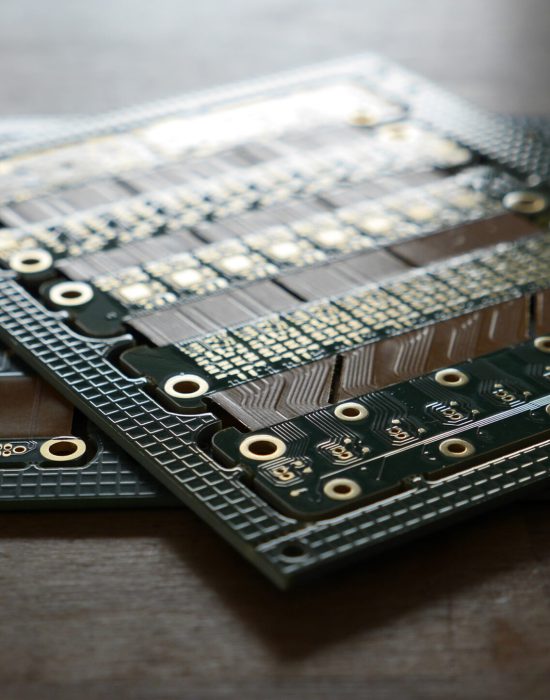

Embedded Components

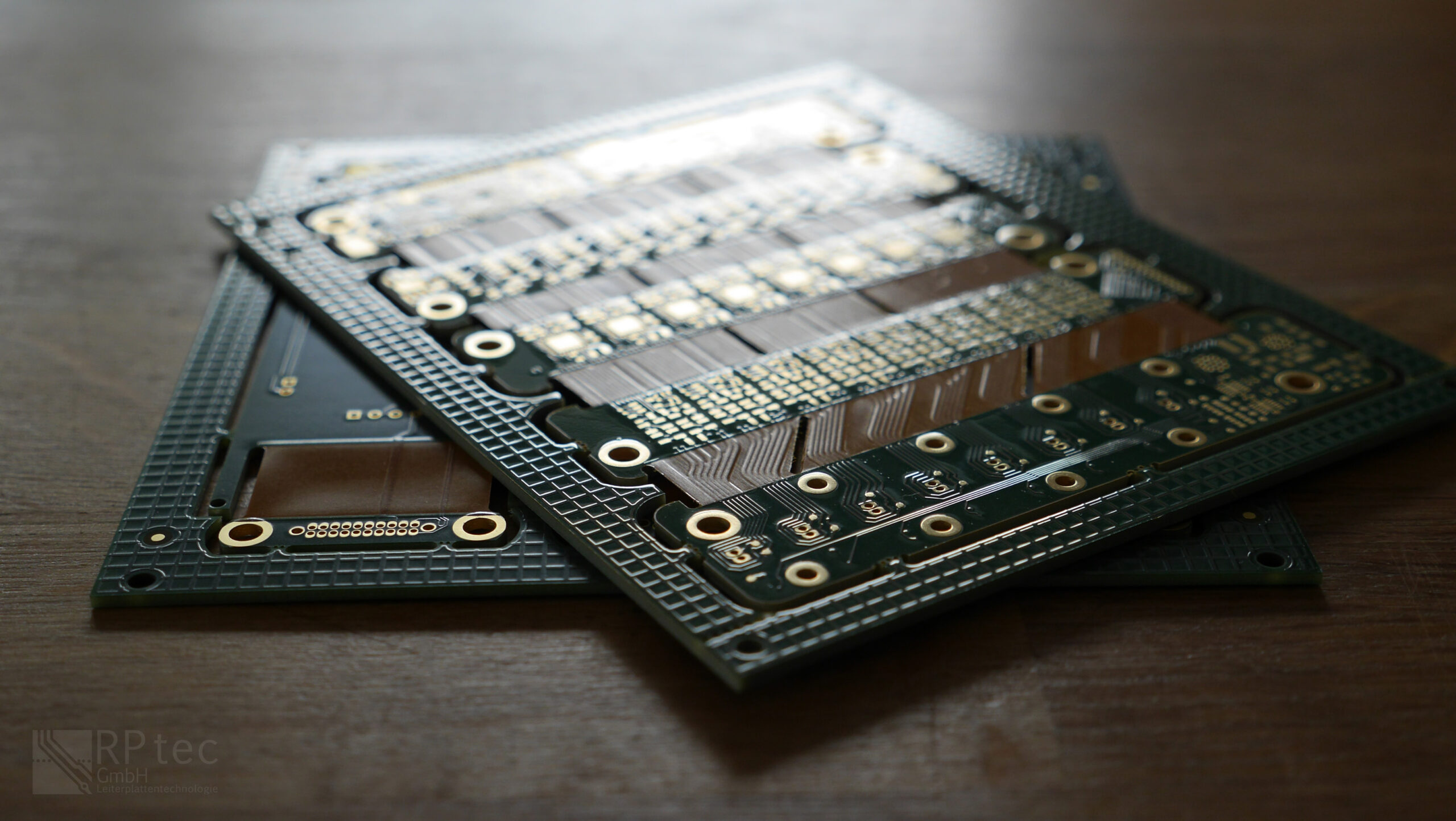

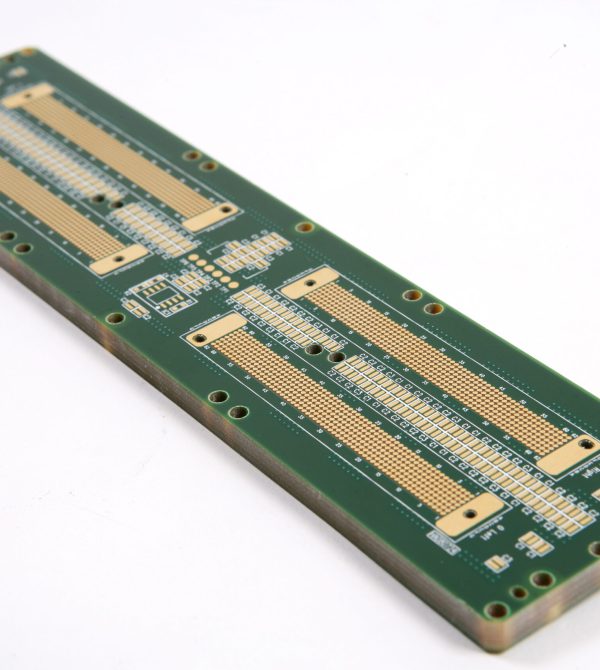

Backpanels und Probe Cards

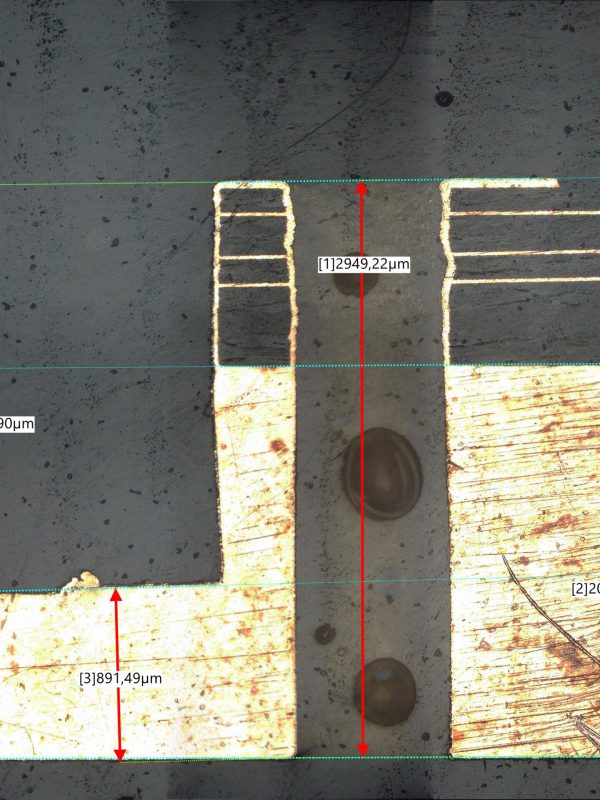

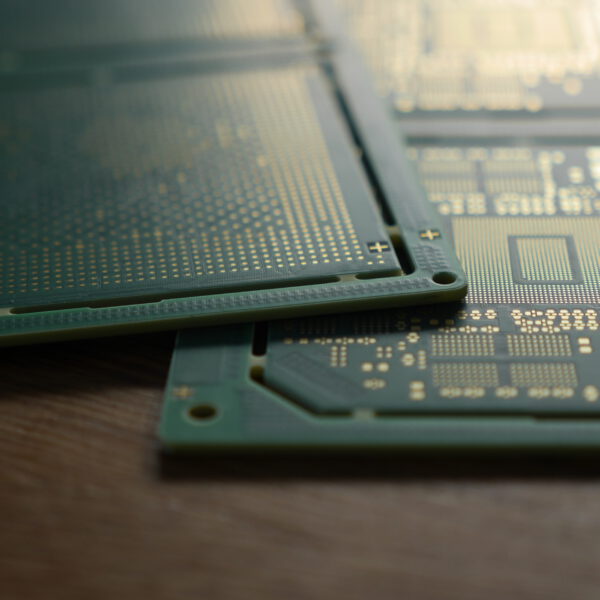

You think your PCB has no more capacity for additional circuits? You thought wrong! Blind vias allow you to pack more functionality into the same space without signal loss or interference. Unleash the hidden potential of your designs and learn how blind vias can help you do it.

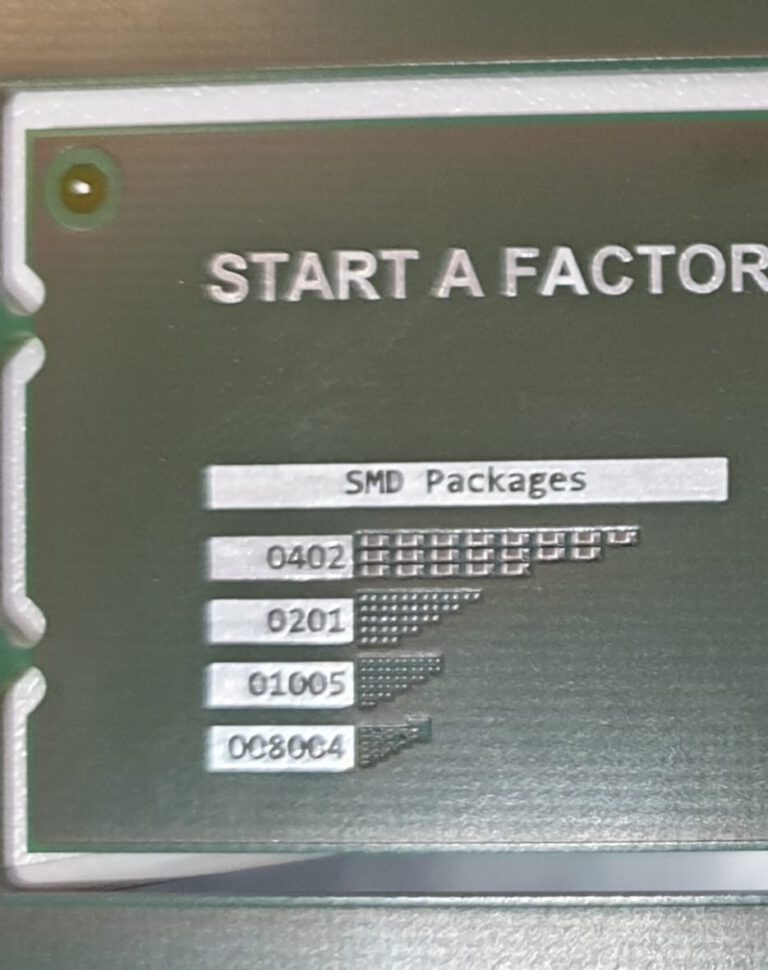

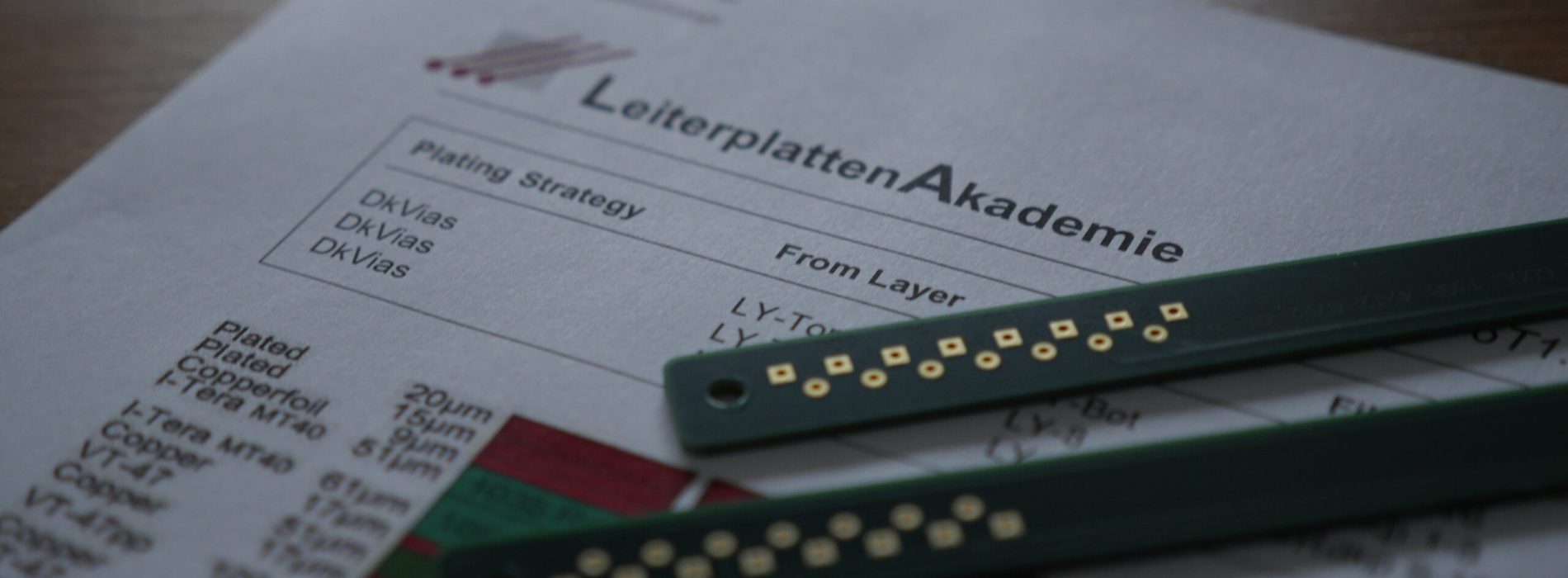

PCB Academy

Through our cooperation with LeiterplattenAkademie GmbH, we can offer you a unique combination of precise layer structure and impedance calculations. Let your projects run more smoothly and avoid delays due to subsequent corrections. Benefit from our expertise and optimise your process!

Certification

| Cookie | Dauer | Beschreibung |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |